Let us put in order some ideas about carbon dioxide, to know better its potentialities and to understand the rules of the game that allow its efficient use, starting from available technologies, to face also, with the due attention, the safety theme, an important chapter for the processing of a refrigerant featuring specific technical characteristics and delicate management

If we trace back a bit of history and we ascertain the first use of CO2, we run the risk of being astonished, because it dates back to about the late Nineteenth Century: they used carbon dioxide mainly in ships’ refrigerating plants because, due to the nature of CO2 itself, with high pressure and 31 °C critical point, condensate was exclusively performed with water.

This refrigerant was actually given up when they started using chlorinated and chlorine-fluorinated gases, because the operation pressures of these gases are much lower and the critical point (that is to say the temperature beyond which it no longer condenses) is much higher, then plant costs were more convenient and the use of these gases generated a real economic efficiency.

However, owing to the progressive prohibition to the use of CFC and HCFC introduced by Montreal Protocol in 1987, many developments occurred and were aimed at decreasing the refrigeration world’s dependence on synthetic refrigerants: various companies in Europe and in Italy (like for instance Costan) already in 1993 started experimenting and producing plants with CO2, which were water-condensed and therefore they always operated in subcritical regime.

A suitable offer of components

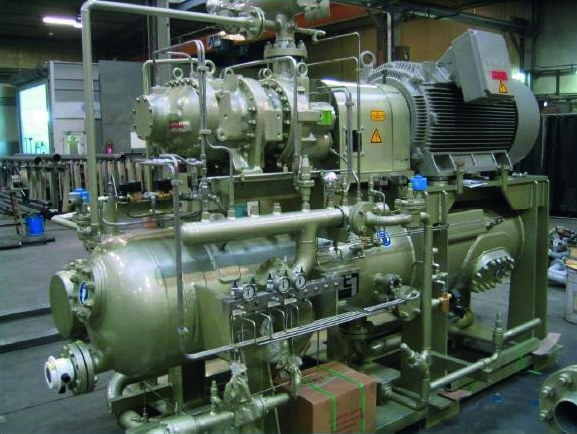

Until a recent past, the use costs of this technology were high, also because there were not many component manufacturers that made product ranges suiting the use of this refrigerant, but in recent times costs are decreasing because almost all component producers offer suitable ranges and, moreover, also many machine manufacturers have a richer and richer range of condensing units; suitable refrigerating systems, chillers and heat pumps for the purpose: nowadays, the latter have excellent efficiency and can produce water with high temperatures.

Therefore, we can state we rely on sufficient technology to be able to manufacture efficient plants with carbon dioxide, but costs (although they have notably dropped) will never be competitive versus those of plants that adopt HFC or HFO as refrigerants, because operation pressures are neatly different and then tubes and the whole circuit must comply with the demanded safety.

We are hereunder analysing (in the limits permitted by the nature of the article) what must be considered in the design, installation and maintenance of a CO2 plant and what using this refrigerant implies.

First of all, as in all pressure equipment and assemblies, the PED certification of the whole is mandatory; in particular, this refrigerant, because of its high operation pressure, almost always makes the whole to be certified belong to the highest categories, therefore the machine must be assisted and checked, depending on situations, by notified Body on each installation (ex. Cat. IV) or subjected to periodical visit and revision on the sample documentation and/or plant, depending on the type of certification and corporate structure.

Implementable plant types with CO2 as refrigerant

Implementable plant types with CO2 as refrigerant

We are proposing hereunder a certainly not exhaustive list but aimed at presenting the most used solutions, remaining anyway confident that the creative phantasy of each technician provided with competence and accuracy allows ideating innovative plants and applications that can lead to use at best one’s own knowledge of the refrigerant behaviour, proposing solutions not experimented, yet.

Subcritical cascade system: cascade systems are composed by two circuits, one of medium temperature and one of low temperature, interconnected by one or more heat exchangers, normally with plates, which on one hand condense CO2 and on the other hand appear as standard evaporators for the medium-temperature circuit.

Ammonia is the most used refrigerant in industrial plants, but it is possible to achieve good results also with R290 (with lower costs than an ammonia solution). It is worth noticing that through the use of these refrigerants, we achieve implementations with fully green environmental impact, because they exploit natural refrigerants, but we can notice that, still today, in conformity with FGAS regulation, fluorinated gases, with GWP not exceeding 1500, can be used, too

The secondary circuit, where we have liquified CO2, can feed Tn utilities (with direct expansion or pumped) and through another refrigeration group (which condenses at the evaporation temperature of the primary circuit), the feeding of low-temperature utilities that also in this case can be with direct expansion or pumped.

What above described is a synthesis of the operation but, since we have always to come to terms with the high pressure of the carbon dioxide and it is always mandatory to have a backup system, that is to say a refrigerating group (sometimes very small) that allows keeping the temperature of the CO2 (generally confined in the insulated liquid receiver) at generally -4 °C , that is to say at around 30 bars. This group must be always powered alternatively by a generator or other backup system, in order to assure always the system operation, especially when external temperatures are high: in absence of operation of the backup group, in a short time we will have the carbon dioxide leakage due to the intervention of safety valves.

Transcritical system, a more complex system to be explained in its general lines, because many are the solutions adopted by various machine designers and manufacturers that can reach the same result. Speaking of efficiency, it is anyway worth considering that – if it worked with this system for the whole year at high temperatures -we would have inferior efficiency to F-Gas based systems, but the prerogative of the transcritical system is precisely that, averaging the external night/day and seasonal temperature, where there can be prolonged operation times under the critical point, it is obvious that the average efficiency becomes very high.

Nowadays the transcritical system has reached a technological level that allows operating also at tropical temperatures, to the extent of making it widely used in numerous plants for the commercial refrigeration and in retail environment. The name comes from the fact it surpasses the critical temperature, therefore, to condense, such devices must be adopted as to succeed in condensing CO2, therefore we have pressures that reach 120/140 bars in the delivery part.

Consequently, compressors, the eventual oil separator, the eventual desuperheating exchanger (heat recovery), the Gascooler up to the HP valve of flash gas must be designed for a work pressure of at least 120 bars. After the HP flash valve, is positioned the liquid receiver, where the pressure drops to around 30/40 bars, depending on design specifications: this fall of pressure, and consequently of temperature, allows the gas to condense: to achieve that, manifold solutions can be adopted like, for instance, to position in the place or concurrently (ruled by the management system) an ejector that, under determinate situations, sucks the gas from the liquid separator, increasing the system efficiency (anyway here each machine manufacturer uses its own methodology).

Prosecuting the plant cycle, in the receiver output we have the line of the liquid, ready-to-use in utilities where, generally due to the increase or simply the regeneration of the gas, the liquid line, before reaching utilities, flows through an exchanger, connected with the suction line (its task is overheating the gas coming from utilities), the so-called regenerator: this device allows an efficiency rise.

The liquid line feeds both utilities at normal temperature, where in output the gas will be sucked by compressors at normal temperature, and utilities at low temperature, where at the output it will sucked by BT compressors.

BT compressors’ delivery, before entering compressors at normal temperature, will flow through a desuperheating device, which is generally air-type: this allows recovering energy, cooling the gas before it is sucked by tn compressors.

As indicated shortly before, the liquid separator mounted before the suction of tn compressors, allows making evaporators work with low overheating, so recovering power: there are also ejectors that suck the liquid from the separator, injecting it directly into the liquid receiver by exploiting the pressure of the gas exiting from the gascooler, so further increasing efficiency. Regarding the latter solution, we are not informed about the possible free use, as covered by patent.

Many are the adoptable technical solutions and we have listed here just a little part. We believe this is a technology that can attract utmost attention, being rich in potentialities, and those who intend to enter this world must not be absolutely afraid, on the contrary, attending appropriate courses and using logic a lot, they have the opportunity of developing extremely interesting solutions: we hope we have sufficiently highlighted the need of working under safety conditions, remembering – fundamental for the use of carbon dioxide – the compliance with PED regulations.

The advantages of using CO2 in refrigerating plants

– The CO2 plant is not subjected to the F-Gas regulation and then it does not need any registration in databank and this determines lower management and bureaucratic costs for customers (operators)

– The refrigerant cost is much lower than fluorinated gases’ admitted by the EU 517 Regulation

– The refrigerant availability is not subjected to any non-availability risk as it is instead happening with HFC

– Carbon dioxide does not generate any flammability problem.

– The evaporation temperature is constant and this determines the absence of Glide problems

– Refrigerating lines have very small sizes compared to the ones of fluorinated gases r134;404; etc.

Salient characteristics of carbon dioxide and some suggestions

– The critical point is determined at the temperature of 31 °C; CO2 does not condense (under normal conditions) above such temperature,

– The pressure at 31 °C is around 72 bars (g)

– Triple point -56.6 °C = about 4.18 bars (g): this is the temperature and the relative pressure at which CO2 solidifies, making its use impossible.

It is necessary to pay utmost attention to limits because in charge phase (most of all in vacuum failure) it is necessary to charge in gaseous status, and never in liquid status, up to the pressure of at least 5 bars, to avoid the solidification.

Some general remarks about the safety theme

– The sometimes-high pressure of CO2 is a very important theme that should be never underestimated: in plant design phase, it is therefore extremely relevant to choose the most suitable material for tubes. A solution may be the choice of a copper type- k65 tube able to bear a pressure up to 120 bars, or stainless steel).

Therefore, it is always necessary to refer to the calculation according to rules defined and released by ASME and to determine thicknesses with the safety margin, then to design the tube path by assessing eventual risks, such as for instance the passage in very hot points (to be eventually reduced by implementing apt insulations) and suitably designing them for preventing mechanical stresses.

– The plant design must convey safety valve exhausts into zones that cannot (in case of intervention) hurt people.

– Still speaking of safety valves, in case of intervention, the CO2 exhaust must be protected by a sort of “muffler” to reduce the generated noise, which might be very annoying for operators.

– Concerning people’s safety, inside the environments where utility elements are installed (cells, counters, chillers and so on) it is always advisable to carry out the calculation accurately, determining the quantity of gas contained is compliant with the table of 378/1 regulation regarding the quantity of refrigerant contained in the plant with regard to environments’ volume.

Anyway, it is always opportune to install some CO2 detection sensors, connected with an alert system, to avoid concentrations and causing problems to people: the suggestion is extended to maintenance, too, and then it is fundamental not to neglect such system and urge the customer to take the responsibility of controlling it periodically, with a register of control activities, to have an element that defines the responsibility burden in case of accidents.

– In the plant safety ambit, in design phase and in the risk assessment stage, it is advisable to always avoid the system remains under pressure and “bottles liquid”. This determines particular attention to the issue of non-return valves (solenoids, taps etc), so that in manoeuvre phase (also wrong) they never permit to close without possible coolant vent, because (owing to the logic effect of the liquid incompressibility principle) the explosion in some points of the evaporator and/or along tubes, and/or in some components would occur. Therefore, it becomes opportune to provide for non-return valves in parallel to components (generally taps) to make the gas flow towards the coldest point (the receiver). As alternative, if what above said is impossible, you should mount a safety valve in the plant part where possibly CO2 is in the gaseous, and not liquid, status, because a safety valve installed in a zone where there is prevailingly liquid, at its intervention, “will shoot” ice arrows and will obstruct the valve conveyance tube towards the outside.